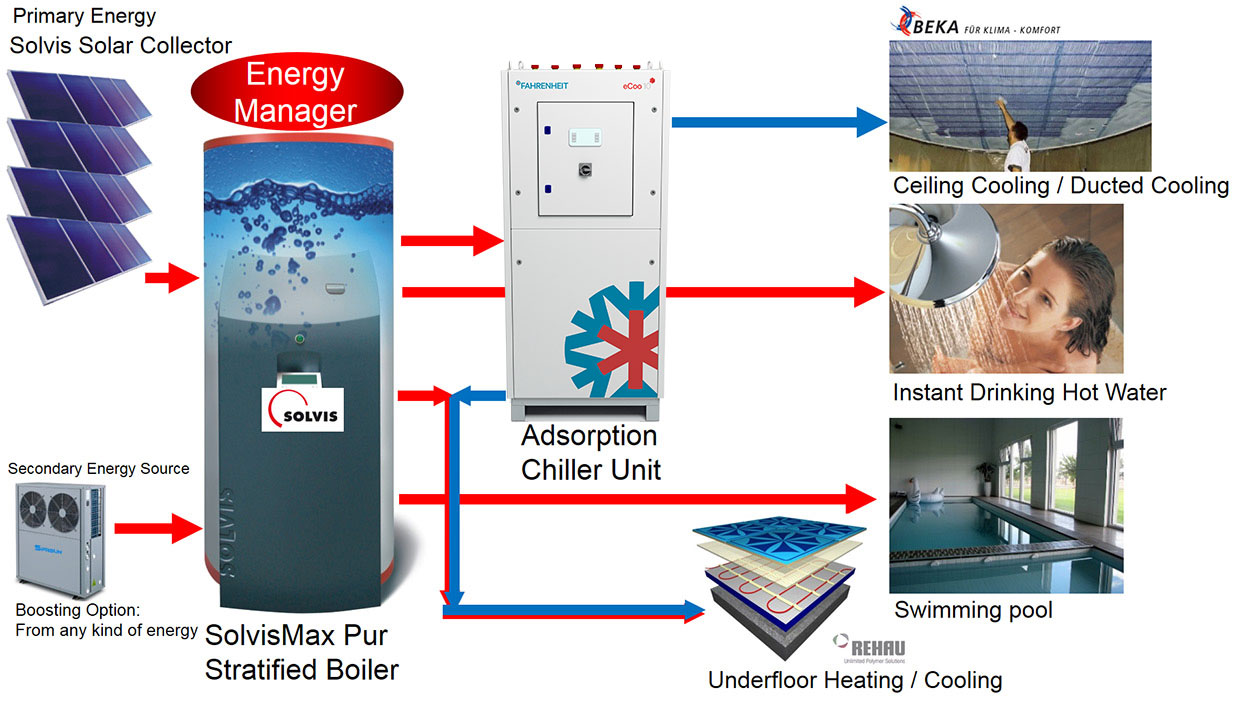

The Fahrenheit Chiller is really a World Wonder – you input Hot Water and Cool Water comes out!

This cooling process is totally mechanical and does not rely on electricity to make cool water. Now this is a very big step in sustainable energy, as a combined Solar Hydronic system with a Fahrenheit Chiller results in FREE Heating & Cooling in most Australian regions!

Thanks to Fahrenheit German engineering, it is only a low energy input of 50°C – 95°C water temperature to get achieve an output of 8 – 21°C chilled water!

The low solar harvesting temperature even on cloudy days from a SOLVIS Solar System in its high flow rate, is enough to supply not only residential homes but even Commercial / Industrial projects up to 240kW!

Quick Example:

For an Australian residential house of 650m2 with sufficient insulation barriers in place, the whole house could be cooled with chilled water between 10-14°C through underfloor pipes or ceiling cooling pipes.

This process would result in a constant and comfortable room temperature, in South Australia if the outside temperature was 42°C and the same cooling input as above, the room temperature can be held at a constant < 22°C.

Discover the potential

See our examples of Fahrenheit hydronic cooling in use

How it works

The mechanics of a module consist of the following 4 phases:

Phase 1: Desorption / Adsorption

The desorber is flooded with hot water (hot-water circuit). As a result the cooling agent, which has accumulated on the inner surface of the silica gel, is being expelled and liquefied on the condensator. The heat that is being generated during the liquefaction is being discharged through the re-cooler.

At the same time, the adsorber adsorbs the water vapor that is being created inside the evaporator when the object to be cooled takes in the heat supplied through the cold-water circuit. The heat that is being created during the adsorption process will be discharged – together with the liquefaction heat – into the environment. Operational phase 1 will run until the required cold-water temperature set point has been reached.

Phase 2: Heat Reclamation

Immediately after phase 1 the 3-way valves in the flow section of the three circuits will be set such that the previously desorbed Adsorber 1 will now be flooded with re-cooling water. The energy, which initially was stored in the desorber, will not be simultaneously claimed at the mean temperature sink; but instead will be pumped in the driving circuit over a period of time.

The return of Adsorber 2, which will be desorbed following the adsorption process, will for a set time supply the re-cooling circuit. Only after a certain temperature difference between the two adsorber returns has been reached, will phase 2 be terminated by switching of the 3-way-valves in the return section of the three circuits.

Phase 3: Desorption I Adsorption

The desorber will be flooded with hot water (drive temperature) and simultaneously adsorbed. The process of adsorption/desorption takes place analogously to phase 1.

Phase 4: Heat Reclamation

Immediately after phase 3 the 3-way-valves will switch in a manner such that the previously desorbed Adsorber 2 will now be flooded with re-cooling water. The heat reclamation process takes place analogously to phase 2.

Operational Setup

From an operational point of view, the Adsorption Chiller Aggregates consists of the following three cycles:

(1) Hot-Water Circuit

By means of the hot-water circuit (driving circuit), thermal energy is being supplied to power the Adsorption Chiller Aggregates and the heat exchange that happens inside of it.

(2) Re-cooling Circuit

The heat that has been supplied to the Adsorption Chiller Aggregates (heat from the object about to be cooled and heat to dry the equipment) will be removed through the re-cooler by redistribution to the environment at mean temperature level.

(3) Cold-Water Circuit

Utilising the cold-water circuit, heat will be removed from the object about to be cooled.

FAQs

Radiant Heating and Cooling in General

What durability does the system have?

50 years and longer – standard operation conditions for radiant heating and cooling provided.

Which capacity do cooling ceilings with capillary tubes reach?

Always sufficiently enough! In standard installations the following capacities are reached (values tested according to EN 14240):

plaster ceiling: 76 W/m2

plasterboard ceiling: 68 W/m2

metal cassette ceiling: 89 W/m2

In the end, the engineer always chooses the right cooling ceiling type in a concrete project considering the actual cooling capacity requirements and ceiling construction.

What can I do to reach more cooling capacity?

Even more cooling capacity? No problem! Only the ceiling construction and temperature difference ΔT between average water temperature and room temperature affect the cooling capacity of a radiant cooling ceiling. Besides raising ΔT, also the convective capacity of the ceiling can be raised by forced or artificially controlled convection. Higher convection can be reached for example by open ceilings or floating ceiling panels.

In this way, cooling capacities of up to 180 W/m2 are possible.

Can I use a cooling ceiling system also for radiant heating?

Naturally, a cooling ceiling system can also be used for heating! Instead of cool water, you only send warm water through the surfaces activated by capillary tubes mats or serpentine copper tubing or the single pipe technology.

With what water temperatures does the system work for radiant heating?

28°C will usually suffice

Radiant Heating and Cooling with Capillary Tube Mats

Is it possible to repair a leaking pipe during or after the installation?

Leaking pipes or fittings are not a problem. It is very simple to repair the leaks. First run the water through the mats in order to see a wet spot on the drywall or plaster. Open this damaged areas, than fused the piping on both sides. This will not affect the capacity for cooling or heating.

What is to do before the start up of the capillary system?

Before the system entry into service the system should be tested against leakiness.

That happened via an air pressure test of 10 bar. In the second steep you do the same test with water.

If you find any leaks it is very easy to repair them.

Can you use the Mat as a Geothermal Absorber?

In general you can use the mat as an absorber. The attributes of Polypropylen do not aloud the direct contact with sunlight. The mats is to protect against direct UV-rays.

How does the capillary tube technology work?

At the heart of the BEKA capillary tube principle is a closed system of thin tubes. Just like blood vessels are located directly under human skin, the capillary tube mats are located just under the surface of walls, floors and ceilings. Cool or hot water flows through the network and supplies the rooms with pleasant temperatures.

In the same way that blood circulation gives life to people, BEKA capillary mats give thermal life to buildings.

Can I connect the capillary tube system to an existente system?

Yes, you can! By using a heat exchanger you can integrate the capillary tube system in every installation. By using non corrosive material in combination with capillary tubes mats you have a very long lasting system.

For more information please visit the Beka website

Technical Information

Please download the PDFs below for more information about this product.

By planning everything right from the beginning, you can achieve zero net energy costs which means the total energy consumed by your house is less than your solar energy collected on sunny days.

Technical Information

Please download the PDFs below for more information about this product.